Manual Book for Linear Type Coffee Capsules Filling Sealing Machine

CONTENTS

1.Introductions

2.Main technical parameters

3.Work principle and structure

4.Use

5.Maintenance

6.Troubles and troubleshooting

7.Electrical schematics and components tables

8.Warranty card

1. Introductions

RML-series coffee capsules filling and sealing machines can be applied to different specifications. The ways of filling are different , such as gravity flow type, filling, measuring cup, negative pressure type, screw type filling, and so on. The ways of filling apply to a variety of different products— drinks, ice cream, jelly, milk, ice cream, butter, jam, rice pudding, rice, cheese, coffee powder and other food as well as medical, chemical products. When filling and sealing medical and chemical products, the machine uses a composite film of the corresponding material.

The machine adopts Japan Omron or Germany Siemens programmable logic control system. The body of the machine uses stainless steel, which is in conformity with the relevant standards of food hygiene. Implementation of equipment parts use Taiwan pneumatic control systems, the mechanical structure is simplified, the failure rate is significantly lower, machine run more smoothly and safely. The quality of filling and sealing is excellent, so that it greatly improves working efficiency and the life of the equipment.

RML-series sealing machine can be designed according to customers’ requirements.

The automatic filling and sealing machine uses the most popular advanced mechanical and electrical control system (PLC), the action completed by motor and the aerodynamic optimization to cooperate. Automatic completion of falling cup, filling, sucking foils, sealing, printing, pushing out the cups and other mechanical functions. Features are compact structure, high automation, easy to use, stable performance, simple maintenance, and high production efficiency and 24-hour continuous work. Components (e.g. Stainless steel, aluminum, copper and other corrosion-resistant) are in line with Food Hygiene Law. It is reliable and ideal for food production line main equipment.

2. Main technical parameters

| Productive ability | 1000 cups/hour |

| Motor power | 3 kw |

| Filling volume | 5-50 grams(can be adjusted) |

| Voltage | 220v/50 hz |

| Dimension | 1700*1180*1600 mm |

| Weight | 800 kg |

3. Work principle and structure

Machine action completed by aerodynamic optimization and maneuver, give full play to the motor system and pneumatic system, smooth and flexible benefits. Control system for intelligent monitoring of all actions, minimize errors due to manual operation of the probability of damage caused by the machine. Each action is divided into manual and automatic operation mode, the operation and commissioning of the machine are very convenient. Sealing temperature by the temperature controller has been set in advance; users do not need to make adjustments.

Machine automatically by the machine frame, falling capsule, filling, suck foils and hot seals and other components. Capsule is automatically fall into the aluminum plate, aluminum plate and a work location, through a screw type filling, mechanical suction cover, automatic sealing work together at the final output.

Heating system: intelligent temperature control device, heating elements, solid state relays, thermocouple, and heat seal temperature can be adjusted (0-400).

Aluminum drive system: driven by air cylinder, pawl clutches and other components, drives the cylinder drive pawl clutch to intermittent movement.

This machine uses 0.6 m3/min air compressor.

4. Use

Connect the filling machine with power, connect an external air compressor air supply, air filter pressure regulation 0.6Mpa, the actuators consist of all of the equipment in the original location. Turn on the power on the control plate.

Through preheating and thermal switch. Preheat temperature and heat seal temperature set at 150 ℃, the temperature reaches a preset value, then the thermostat at between 160-250 ℃ (depending on the sealing film material and thickness of the different set of temperature, generally higher thickness thicker heat seal temperature).

After pressing the “English” command, the main page will be presented to you.

Enter the main menu

press the “point control” of entry control interface.

Select each button and view each stations corresponding to the button is working correctly, the process should observe the corresponding change in functioning of the actuator. Component is running smooth, stable, and fastening bolts are loose, pipe connection sections have no gas leakage, if abnormality was detected should promptly stop and take the appropriate measures to adjust the equipment, ensure that the devices can run smoothly and safely. Returns to the main menu after the test is completed.

From the “main menu” or “point control” into the “Time settings”, sets fall Cup and sealing time, the factory settings.

When finished, return to the main menu. “Manual/auto” switch is in the “auto” position, place the empty capsules in Capsule Department is automatically, place the foils placed in the automatic foils unit, filling coffee powder into the hopper. Then press “start” switch, the device is already in a State of automatic cycle, press the appropriate switches according to an empty capsule to move to the location, filled and sealed are automatically derived from the machine end automatically.

Installment

- After machine was carried to production department. Put the nut in to four holes on the bottom of machine.

- Adjusting the nut until the machine on horizontal position.

- Join line to the electric box where has power marked, and connect the ground wire to earth. according to schematic diagram to connect the tube where input the food material on the tank, After it is all finished, we can begin operation.

- In order to make sure the machine run properly and have long working life, please strictly keep the rules of using, maintenance.

- Add a few lubricating oil in the moving chain and guide lever.

- Please clean machine with water before or after using to make sure the food is cleaner.

- Don’t break or scratches the surface of the under of sealing copper, .keep the under of sealing copper is clean.

5. Maintenance

1.Boot, all the moving parts of the refueling time.

2.Before start-up, clean up the sealing hot head open net. To prevent the impact of sealing effect.

3.In turn, check whether there are pieces of double oil.

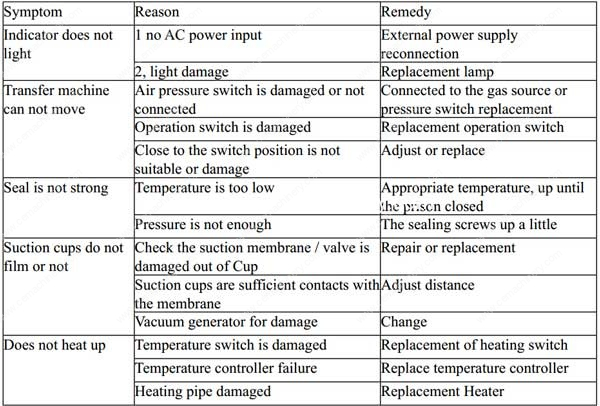

6. Troubles and troubleshooting

7. Electrical schematics and components tables

8. Factory warranty from the product from sale, according to state regulations to implement three guarantees, which reads as follows:

1.User configuration machine, you must operate strictly according to instructions.

2.In the warranty period, the user fails to use the manual for proper operation,

maintenance, maintenance parts, or replace them without permission, resulting in damage is not a warranty. But the factory can be repaired, to be charged the cost of repairs.

3.Warranty period, machine parts warranty for one year, electrical components warranty for 1 year.

Company Profile

Romiter Group is a market leading designer and a manufacturer of coffee capsule filling sealing machinery, include coffee capsule packing machine, coffee capsules filling sealing machine, nespresso capsules filling sealing machine, k-cup filling sealing machine, lavazza blue capsules filling sealing machine, coffee pod filling sealing machine, round shape coffee pod packing machine, coffee bean roasting machine, coffee capsules carton box packing machine.