Users’ Manual for Rotary Type Coffee Capsule Filling Sealing Machine

Table of Contents

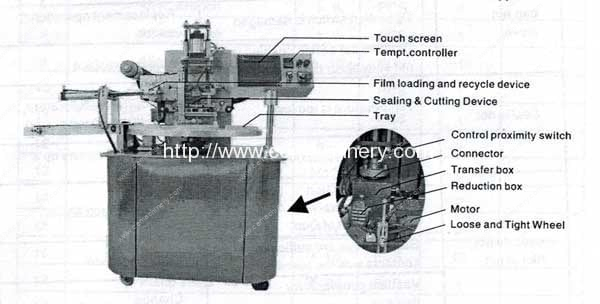

1. Introductions of Rotary Type Coffee Capsule Filling Sealing Machine

Romiter automatic coffee capsule filling and sealing machine uses the most popular advanced mechanical and electrical control system (dual control PLC), the action completed by motor and the aerodynamic optimization to cooperate. Coffee Capsule Filling Sealing Machine can automatic complete delivery cup, falling cup, capsule filling, mechanical hand suck film, sealing, hand out the cups and other mechanical functions. Features are compact structure, high automation, and easy to use, stable performance, simple maintenance, and high production efficiency and 24-hour continuous work. Components (e.g. Stainless steel aluminum copper and other corrosion-resistant) are in line with Food Hygiene Law. It is reliable and ideal for coffee capsule making business.

2. Work Principle and structure of Rotary Type Coffee Capsule Filling Sealing Machine

Machine action completed by aerodynamic optimization and maneuver, give full play to the motor system and pneumatic system, smooth and flexible benefits. Control system for intelligent monitoring of all actions minimizes errors due to manual operation of the probability of damage caused by the machine. Each action is divided into manual and automatic operation mode, the operation and commissioning of the machine are very convenient.

Sealing temperature by the temperature controller has been set in advance; users do not need to make adjustments.

3. How to Use

1) Machine connected to the gas pressure to open source to ensure that O.75-0.85Mpa pressure.

2) Check the power switch and that manual / off / auto switch in the stop position.

3) AC 220V power supply plug into the machine’s single-phase three-wire outlet make sure the ground is good.

4) Switch the control panel on / off / auto to manual position turn the power switch power indicator lights at the moment.

5) 0pen the thermostat switch set the seal and make electric heating elements begin heating about 5minutes up to the setting temperature.

6) Waiting the seal head heat to the setting temperature (Green light on the thermograph turns offered light on).

7) lf the manual /off / auto switch to manual position hand pressing enable switch (sending cup) cup light at this time to send the machine began to get cups, put the lid pressing enable switch the machine began to complete the same actions to put cover Other actions the same mode of operation.

8) A free hand by enabling any switch (seal 1, seal 2, off the cup, smoke film, filling) corresponding to the light, the machine began to perform the appropriate procedures.

9) The manual / off / auto switch to the automatic position then the machine will automatically complete the various procedures. Products to be sealed sent from the office to check out the cup seal is solid and make appropriate adjustments according to specific circumstances.

RMY Series Full-automatic Coffee Capsule Filling and Sealing Machines(Rolled Film Type)

RMY Series Full-automatic Filling and Sealing Machines(Pre-cutted lids typel)

4. Maintenance

1. Boot all the moving parts of the refueling time.

2. Before start-up, clean up the sealing hot head open net to prevent the impact of sealing effect.

3. In turn, check whether there are pieces of double oil.

5. Troubles and troubles shooting

| Symptom | Reason | Remedy |

| Indicator does not light | 1 no AC power input | External power supply reconnection |

| 2 light damage | Replacement lamp | |

| Transfer machine cannot move | Air pressure switch is damaged or not connected |

Connected to the gas source or pressure switch replacement |

| Operation switch is damaged | Replacement operation switch | |

| Close to the switch position is not suitable or damage | Adjust or replace | |

| Seal is not strong | Temperature is too low | Appropriate temperature up until the prison closed |

| Pressure is not enough | The sealing screws up a little | |

| Suction cups do not film or not | Check the suction membrane I valve is damaged out 01 Cup | Repair or replacement |

| Suction cups are sufficient contacts with the membrane | Adjust distance | |

| Vacuum generator for damage | Change | |

| Does not heat up | Temperature switch is damaged | Replacement of heating switch |

| Temperature controller failure | Replace temperature controller | |

| Heating pipe damaged | Replacement Heater |

6. Electrical schematics and components tables

| No. | Name ay | Type umber | Quantity | Remarks | |

| 1 | Air Switch | 3P16A | 1 | PCS | |

| 2 | Temperature controller | XMT D-8181 | 2 | PCS | |

| 3 | Touch screen | Delta | 1 | PCS | |

| 4 | Solid State Relay | DZ40A | 2 | PCS | |

| 5 | Programmable controller | PLC | 1 | PCS | |

7. Random Accessories

| No. | Name | Model | Unit | Quantity | Remarks |

| 1 | Allen wrench | φ2 | PCS | 1 | |

| 2 | Allen wrench |

φ3 | PCS | 1 | |

| 3 | Allen wrench |

φ4 | PCS | 1 | |

| 4 | Allen wrench |

φ5 | PCS | 1 | |

| 5 | Allen wrench | φ6 | PCS | 1 | |

| 6 | Allen wrench | φ8 | PCS | 1 | |

| 7 | Allen wrench | φ10 | PCS | 1 | |

| 8 | ” A ‘ screwdriver | PCS | 1 | ||

| 9 | ‘Ten’ screwdriver | PCS | 1 | ||

| 10 | Thermocouple | K- | PCS | 2 | |

| 11 | Trachea | M12 | PCS | 3 | |

| 12 | Sucker | PCS | 2 | ||

| 13 | Heating block |

110V | PCS | 2 | |

| 14 | Pump seals | φ65 | PCS | 10 | |

| 15 | Pump seals |

φ26 | PCS | 1 | |

| 16 | Single-phase three -wire outlet | PCS | 1 | ||

| 17 | Proximity switch | PCS | 1 | ||

| 18 | Component pins | PCS | 20 |

8. Factory warranty:

1) User configuration machine, you must operate strictly according to instructions.

2) ln the warranty period, the user fails to use the manual for proper operation, maintenance, maintenance parts, or replace them without permission, resulting in damage is not a warranty. The factory can apply repairing, but to be charged th cost.

3) Warranty period- machine parts warranty for one year, electrical components warranty for six months.

Send Us Inquiry to Get Quotation