Manual of Semi-Auto Coffee Capsules Filling Sealing Machine for Nespresso, Lavazza, Kcup

Contents

Ⅰ.Usage and Feature

II. Main Parameters

III. Structure and principle

IV. Installation and Adjustment

V. Maintaining

VI. Breakdown and Solutions

VII. Electronic Diagram and Electronic Parts List

VIII. Packing List

Table of Contents

I. Usage and Feature

RMS Semi-automatic Rotary Type Filling and Sealing Machine have the functions of manual turn rotary board, automatic filling and sealing. It adopts intelligent temperature controller, the temperature error ≤±1%, strong sealing function. It uses JAPANESE OMRON PLC. Fuselage of Stainless steel is up to food standard. The usage of pneumatic parts simplifies the mechanical structure and decrease the breakdown. The performance of the machine is more stable and safe. Automatic flow filling without spray or leaking, excellent sealing, increase the capacity and longer the machine life.

The machine can use aluminum foil or aluminum film or roll of plastic film, it is widely used in beverage, milk and food industries.

II. Main Parameter

Rotary speed: 10 rounds/min

Output: about 600 cups/hour

Filling volume: 5-30g (customized according to the cup size)

Heating power consumption: 1kw

Air consumption: 0.3 m³/min

Voltage: 240V, single phase, 50HZ

Machine size: 800mm x 600mm x 800mm

Weight: 90Kg

III. Structure and Principle

1. Structure

Refer to whole machine structure (FIG 1) and Sealing and Cutting Structure

The whole machine is composed of main body, automatic gravity filling system, automatic sealing system. The cup is put manually in the cup mold on the aluminum board, the board turned manually one station ahead, the filling piston begins to work (filling volume can be adjusted by the cylinder valve), the sealing works at the same time, the cup taken out manually.

Heating system: It is composed of intelligent temperature controller, heating element, solid booster and thermo couple. The heating temperature can be adjusted between 0-300℃.

The machine connects 240V 50HZ Single phase alternating currents, the capacity of air compressor must be bigger than 0.4 m³/h.

2. Principle and Usage

Turn on “power” switch, the power indicating light is on. Connect the air compressor to the machine, adjust the air filter pressure to 0.65Mpa (it is adjusted before going out the factory), the whole machine is on the original working condition.

Turn on Heating switch, the heating indicating light is on. Set the temperature to 150℃, when the temperature reaches the setting temperature, then adjust the temperature to 160-250℃ (set the temperature according to the material and thickness of the foil/film, the thicker the foil/film, the higher the temperature is). The average temperature is 180℃.

The sealing time can be adjusted in PLC, adjust the time according to the sealing effect.

The filling volume can be adjusted by the valve.

When operating the machine, check the working condition such as running of the spare parts, the fixing of the screws, air pipe connection. If anything wrong, stop the machine immediately and fix it, then restart the machine.

When the temperature reaches the setting temperature, put the cups into the cup mold, install the film on the film set or put the foils in the foil setting system, turn the rotary board, the indicating light is on, the machine is on automatically filling and sealing, the finished products should be taken out manually.

IV. Installation and Adjustment

1. After opening the package, check the spare parts first to make sure you get all the parts. Check the screws tight or loose, check the operation of the parts.

2. Adjust the temperature according to the thickness of the film/aluminum foil. Adjust the volume by the cylinder valve. The temperature time and sealing time can be adjustable.

V. Maintaining

1. Check the air source pressure before running, the average air pressure should be 0.6-0.7Mpa. To insure the good working of the cylinder, drain the waste water in the filter regularly.

2. After working, let the heating part cool on room temperature. Clean the filling tank with hot water and drain the water. Clean the aluminum board to prevent corrosion and aging.

3. Clean the heating part to better the sealing effect.

4. Connect the machine earth wire properly to safe using.

5. Set the sealing temperature from low to high to insure the sealing temperature more even and better sealing effect.

6. Stop the machine immediately when breakdown happens, the whole machine is on reset condition, shut down the power and check the breakdowns. After fixing, restart the machine.

VI. Breakdown and Solutions

| Breakdown | Cause | Solution |

| The power indicating light is off when turn on “power” switch | A. power switch bad contactB. the light breaks down or welding loose | A. change the switch or fix the switch touch pointB. change the light or re-welding |

| Filling volume inaccurate | A. valve not adjust properlyB. B. filling solenoid valve core has stain or coil burned | A. Readjust the valveB. Clean the core and change the solenoid valve |

| Bad sealing | A. sealing temperature too lowB. sealing spring ages

C. the film and the material of the cup not match |

A. adjust the sealing temperatureB. change the sealing spring

C. change the film |

| Temperature controller not work | A. the temperature switch burnedB. heater burned

C. temperature controller breaks D. thermo couple not connect properly or breaks |

A. change the switchB. change the heater

C. repair the temperature controller or change it D. reconnect the wire or change the thermo couple |

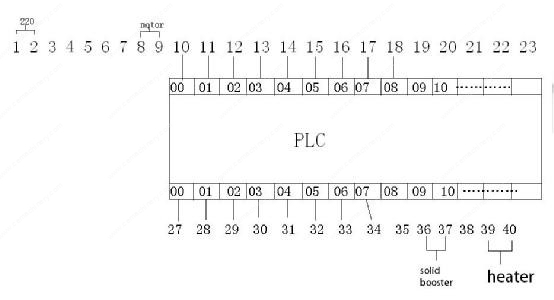

VII. Electronic Diagram and Electronic Parts List

1. Electronic Diagram

2. Electronic parts list

| No. | Part Name |

| 1 | Solid booster |

| 2 | PLC |

| 3 | Button with indicating light |

| 4 | Intelligent temperature controller |

| 5 | Thermo couple |

| 6 | heater |

| 7 | Power switch |

VIII. Packing list

| Description | Model | Quantity |

| Rotary cup filling and sealing machine | RMF | 1Set |

| Operation Manual | 1Pc | |

| internal hexagonal wrench | M4 | 1Pc |

| internal hexagonal wrench | M5 | 1Pc |

| internal hexagonal wrench | M6 | 1Pc |

| internal hexagonal wrench | M8 | 1Pc |

| internal hexagonal wrench | M10 | 1Pc |

| External hexagonal wrench | 14-17mm | 1Pc |

| External hexagonal wrench | 19-22mm | 1Pc |

| External hexagonal wrench | 24-30mm | 1Pc |

| “+” shape screwdriver | Size 6 | 1Pc |

| “-” shape screwdriver | Size 6 | 1Pc |

| Thermo Couple | K type 1.5m | 1Pc |

| Heater | Φ12×95 220V 400W | 1Pc |