Romiter K-Cups Production Machine uses the most popular advanced mechanical and electrical control system (dual control PLC), the action completed by motor and the aerodynamic optimization to cooperate.

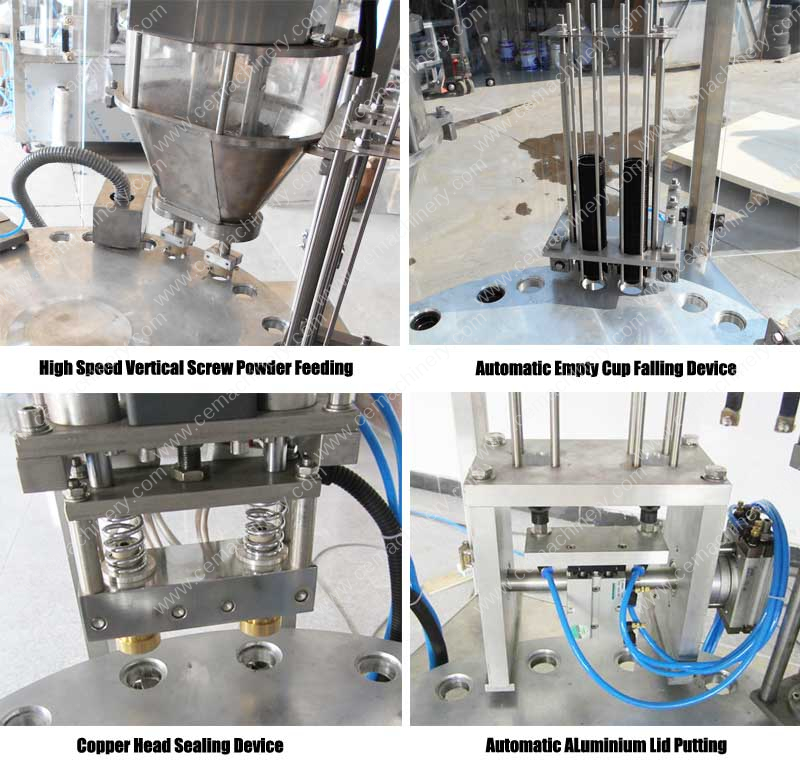

K-Cups Production Machine can automaticly complete delivery cup, falling cup, capsule filling, mechanical hand suck film, sealing, hand out the cups and other mechanical functions. Features are compact structure, high automation, and easy to operate, stable performance, simple maintenance, and high production efficiency and 24-hour continuous work. Components (e.g. Stainless steel aluminum copper and other corrosion-resistant) are in line with Food Hygiene Law. It is reliable and ideal for coffee capsule making business.

Table of Contents

Function of K-Cups Production Machine

Delivery Package of K-Cups Production Machine

A layer of plastic wraps to protect machine from dust, moisture and corrosion. Wooden case as the outside package. 1 set/wooden case

Packing size:1500*1500*1950mm

Packing weight:30-40kg/empty wooden case

Parameter Table of K-Cups Production Machine

| Model | RMY-1 | RMY-2 | RMY-3 |

| Filling heads | 1 | 2 | 3 |

| Capacity(pcs/hour) | 1200 | 2400 | 3600 |

| Filling volume | 3-30g | ||

| Accurate | ≦±0.2g | ||

| Power | 2.5kw | 3kw | 3.5kw |

| Power source | AC 380v/50 Hz 3 phases | ||

| Air consumption | 0.7m3/min | ||

| Heating temperature | 0-400℃ | ||

| Weight | 600 kg | 650kg | 700kg |

| Dimension(mm) | 1660*1090*1700 | 1700*1190*1700 | 1800*1290*1700 |

Working Video of K-Cups Production Machine

Company Profile

Romiter Group is a market leading designer and a manufacturer of coffee capsule filling sealing machinery, include coffee capsule packing machine, coffee capsules filling sealing machine, nespresso capsules filling sealing machine, k-cup filling sealing machine, lavazza blue capsules filling sealing machine, coffee pod filling sealing machine, coffee pod packing machine, coffee bean roasting machine, coffee capsules carton box packing machine.